Projects

We are confident that you will get more than you paid for in terms of quality and customer service. We secure the services of the industries top welders in order to provide you with the best experience possible. You are in good hands when you work with Absolute Welding and Fabrication LLC.

Prior:

BAKERY TANK

We were contracted to demo an existing tank while the bakery was still in operation. This was a 2 day project including demo and install, while the outside temperature remained below freezing in order for the bakery to continue operating while we worked. The new tank was fabricated on site from 1/4" plate with several stiffeners and baffles.

Bellevue Pipe line (City of Greeley)

Install approximately 6 miles of 30”-60” pipe welded inside.

Fort Collins, Colorado

Blue Fab

This was a prototype of an Air Scrubber for a waste water plant. Cheyenne, Wyoming

CC&V GOLD MINE: CRIPPLE CREEK AND VICTOR

We were asked to assist with shut downs and tie-ins, this included pipe from two inch stainless steel pipe up to thirty six inch carbon steel pipe. We also helped with the installation of pipe carrying a cyanide and water solution for processing gold.

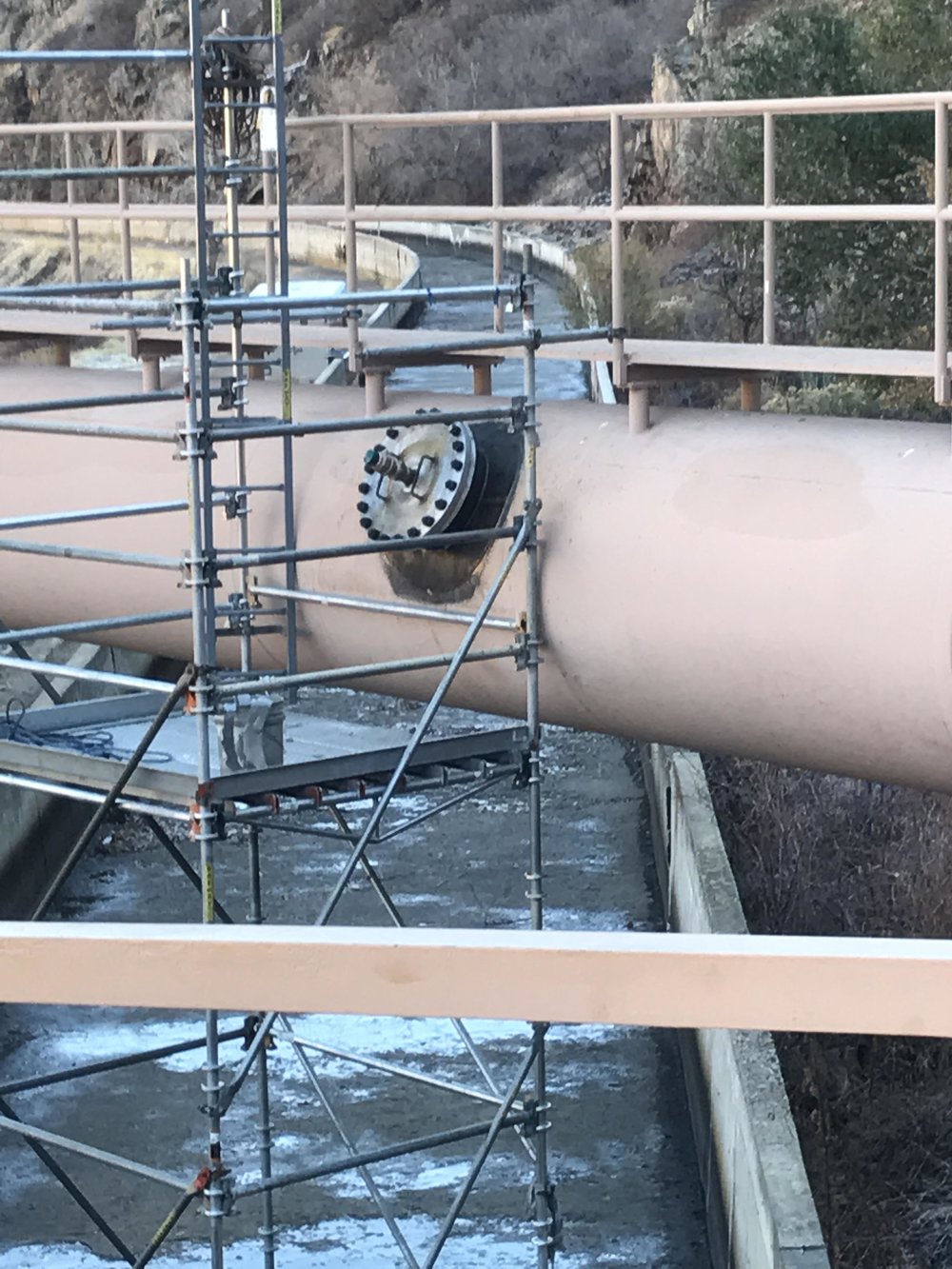

Coblaco Services

60” aerial crossing

Install two 30” access man holes on existing 60” pipe built in 1908 and cut in a temporary 40”x 60” equipment access and weld back after lining completion.

Waterton Canyon, Colorado

GARNEY CONSTRUCTION: ARIZONA

Val Vista water transmission main

Installed 5 miles of 42-60” interior welded pipe line. This was a two year project as the pipe line was installed in the middle of a major roadway.

Mesa, AZ

GARNEY CONSTRUCTION: NORTH TREATMENT PLANT(NTP)

This Waste Water Treatment Plant is the biggest plant to be built in northern Colorado for MWRD. We were asked to take over the project and help get the contractor back on schedule as the last company was not able to maintain the schedule at the pace needed. This project has a large variety of pipe, sizes and types such as carbon steel and stainless steel. The estimated quantity of pipe is approximately 132,000 linear feet of pipe from the smallest plastic pipe to the largest steel pipe.

Hillcrest Water Treatment Plant

36”to 90” pipe welded inside and outside and welding inside of three 15 million gallon tanks.

Denver, Colorado

Hydro Construction

Estes Park Waste Water Treatment Plant

Installed low profile 20” access man ways on to five existing 60” surge tanks.

Estes Park, Colorado

Marston Water Treatment Plant

Gateway Company of Utah

Repairing welds on an existing steel tank and install plates to cover hand holes on dome roof.

Denver, Colorado

Penrose remodel

Contracted to fabricate and install custom hand rail and grab rails using Stainless Steel square tubing.

Centennial, Colorado

R&D Pipeline

DEN concourse A expansion

Relocate and install new 4”-6” water lines for fire hydrants on Concourse A.

Denver, Colorado

Reynolds Construction

Ridgegate and WRCP pipeline

Install approximately 11 miles of 24”up to 54” water pipe welded inside and outside.

Parker, Colorado

SENECA COMPANY: AGFINITY BULK PLANT

We were recommended to do this project from another welding company, the project was five above ground Diesel storage tanks that needed to be combined into two distribution lines with meters. This project consisted of three inch standard pipe and various fittings, fabricating manifolds with meters, valves etc. This was a design build job with as built drawings after completion.

SOUTHERN DELIVERY SYSTEM (SDS)

SDS is a regional delivery system that will transport water to Colorado Springs, Pueblo West, Security, and Fountain. This pipeline includes 66" up to 1/2"thick pipe, the bulk of the line is a weld after back fill. This process is done by installing the pipe then burying it and then the welders set up on the inside of the pipeline to weld the interior joints. This allows the contractor to keep laying pipe without having to wait for the welders to keep up. Our part of this job has included welding on the test heads at the beginning and end of the pipeline for a pressure test. After the pressure test we will cut off the test heads and install the last sections of pipe to tie-in.

Southwest Pipeline Project

Install two 36” tapping saddles onto existing 36” live line.

Dickinson, North Dakota

UIT Maitland Siphon

Weld 140”x 3/4” thick pipe joints on a 15% and 35% slope.

Loveland, Colorado

Wemlinger Water Treatment Plant

36”x 3/4” thick pipe up to 60” pipe welded inside and outside.

Aurora, Colorado

Additional Waterlines

This is our main area of focus. We are highly regarded through out the industry for our quality and high production rates. We work with General Contractors in scheduling to achieve a project with little or no down time.

CERTIFICATION

DO YOU HAVE A PROJECT WE CAN HELP WITH?